Product images :

Our business :

After procuring and grinding silicon nitride powder, we proceed with granulation, sintering, HIP treatment, and cleaning before inspecting and shipping. Our company does not perform polishing for bearing balls.

Feature :

Silicon nitride ceramics often develop a damaged layer (referred to as ‘snowflake’) on the surface after sintering. Removing this damaged layer requires significant material removal, resulting in extended polishing times. However, our proprietary technology allows us to make the damaged layer of silicon nitride blanks very thin or free to create silicon nitride spheres without the need for excessive material removal. This significantly reduces the amount of material that needs to be removed and eases the burden during polishing.

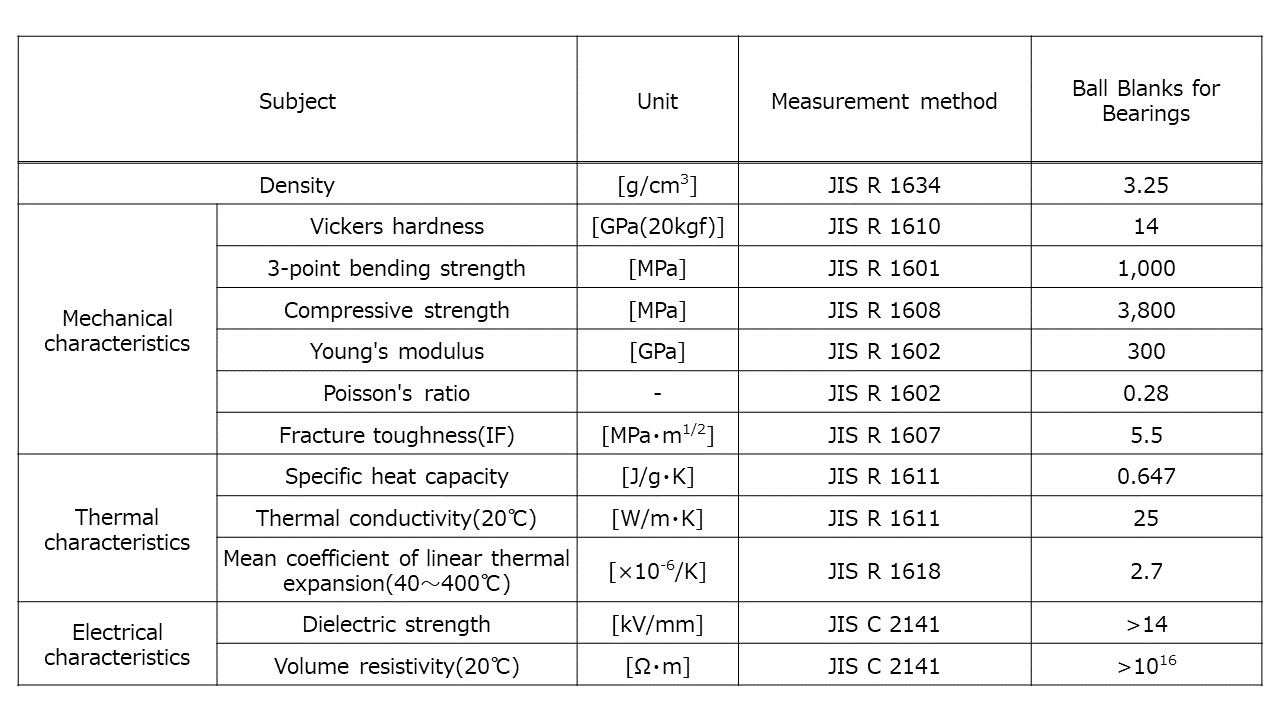

Physical Properties Table :

Note : The figures here are reference values.

Sphere equivalent diameter :

We can consider and develop new balls along with your diameter request.